Installations of production halls and automated lines

Galvanising, painting and blasting lines.

Pneumatic and electric conveyors, kilns, heating, cooling engine rooms and purification plants.

We possess the proper expertise to perform our work well, operating in the field for 21 years. That represents many completed projects and satisfied clients. We are actively involved in the production of the cars, buses and trains that you travel and the planes that fly over your head every day.

The exact number of specialised workers is hired for each installation, and we can provide up to 150 skilled workers for large-scale projects.

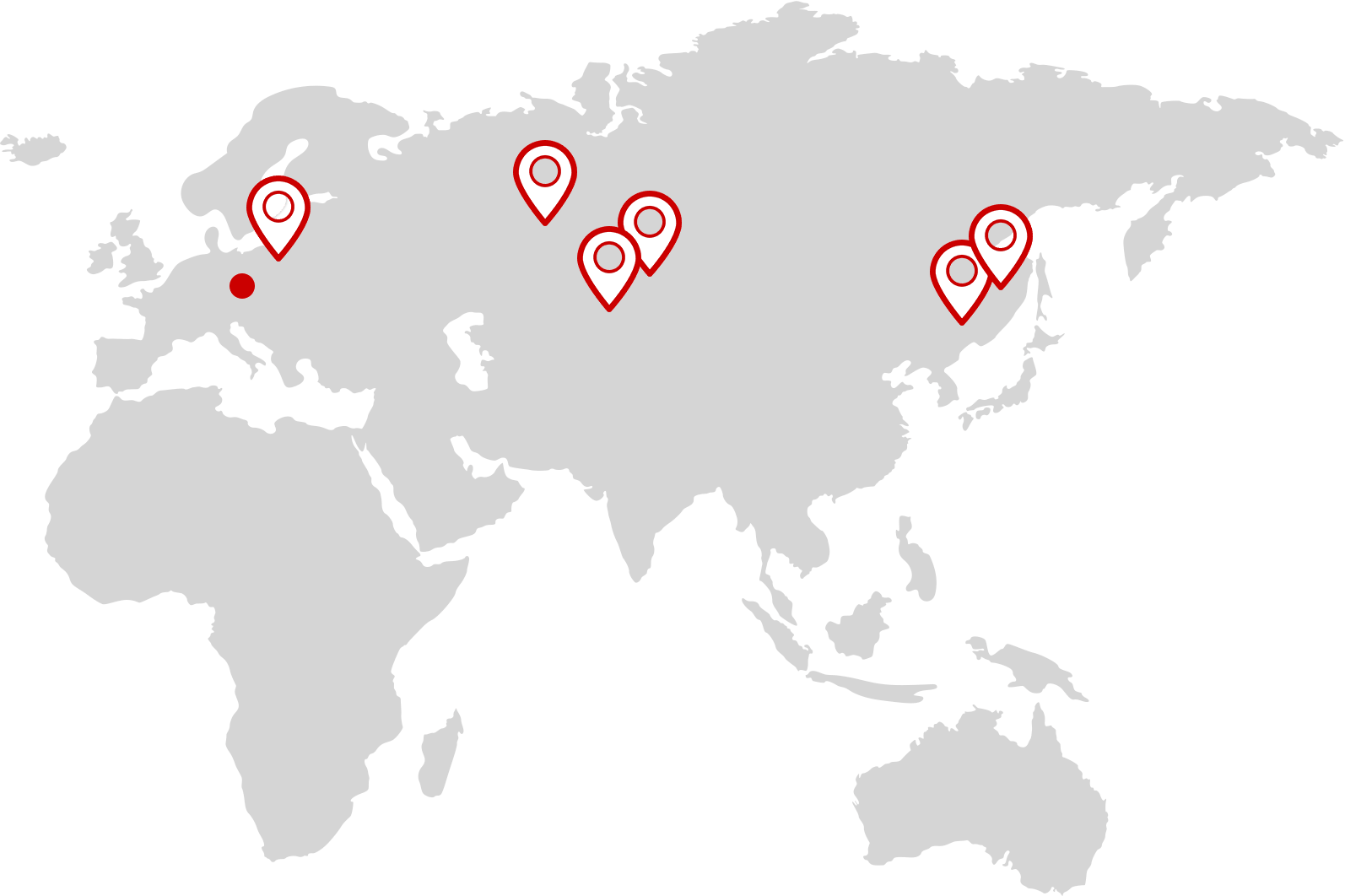

We have realised constructions as far as 8,755 km away from our Company. The distance is not an obstacle for us, only the goal, i.e., the completed installation, is what is important.

We really know our work

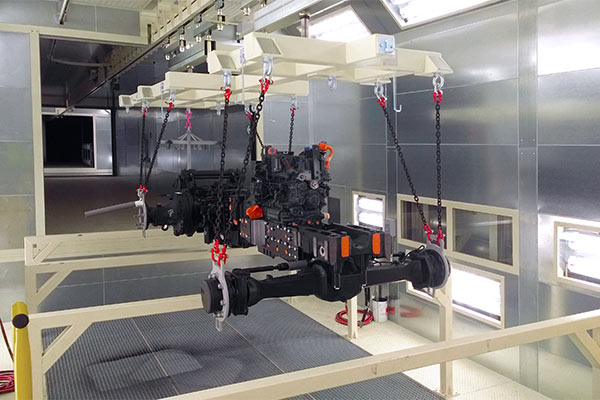

The aviation component modification line made for KNAAZ is the largest structure we have implemented thus far.

Parts travel on a conveyor with a total length of 2.5 km. The entire structure has two levels, which are connected by two elevators, and includes two robotic boxes for painting parts, a volatilisation chamber, a kiln and a galvanisation system comprising a total of fifteen tanks.

Over a hundred employees were involved in the construction of the line under our supervision.